附件四学术论文

Materials Performance and Characterization

Zhiyuan Yang,1 Hua Liu,2 Liwei Ye,2 and Kai Chen2

DOI: 10.1520/MPC20150032

Impact of Synthetic Hydrocarbon in Biofuels on Two

Polysulfide Aircraft Fuel- Tank Sealants

VOL. 4 / NO. 1 / 2015

Materials Performance and Characterization

doi:10.1520/MPC20150032 / Vol. 4 / No. 1 / 2015 / available online at www.astm. org

Zhiyuan Yang,1 Hua Liu,2 Liwei Ye,2 and Kai Chen2

Impact of Synthetic Hydrocarbon in Biofuels on Two Polysulfide Aircraft Fuel-Tank Sealants

Reference

Yang, Zhiyuan, Liu, Hua, Ye, Liwei, and Chen, Kai, “Impact of Synthetic Hydrocarbon in Biofuels on Two Polysul?de Aircraft Fuel-Tank Sealants,” Materials Performance and Characterization, Vol. 4, No. 1, 2015, pp. 236–244, doi:10.1520/MPC20150032. ISSN 2165-

3992

Manuscript received June 13, 2015; accepted for publication September 23, 2015; published

online November 17, 2015.

The Fuel and Chemical Airworthiness Certi?cation Center of CAAC, Beijing, China (Corresponding author).

The Fuel and Chemical Airworthiness Center of the Civil Aviation Administration of China, Beijing, China,

e-mail: yzy42@163.com

ABSTRACT

The impacts of synthetic hydrocarbon in biofuels on two fuel-tank polysul?de sealants were systematically studied in this research. Synthetic hydrocarbon was derived from waste oils and fats and produced by hydroprocessed esters and fatty acids process (HEFA). The experimental results revealed that the volume of two polysul?de sealants shrunk after being immersed in the pure biofuels for 28 days at 93○C. Furthermore, mechanical properties, such as elongation rate and hardness, failed to satisfy the requirement of the speci?cation. The experimental results also showed that the volume swell of two polysul?de sealants varied from jet reference fuel (JRF) more than 5 % after being immersed in the blended fuels when neat biofuel component was mixed with No. 3 jet fuel in a volume ratio of 50/50. The mechanical properties

of elongation and hardness still cannot meet the requirements of the speci?cation. The results demonstrated that synthetic hydrocarbons in biofuels would have a signi?cant impact on the polysul?de sealants of the aircraft fuel tank.

Keywords

synthetic hydrocarbon, biofuel, polysul?de sealants

Copyright VC 2015 by ASTM International, 100 Barr Harbor Drive, P.O. Box C700, West Conshohocken, PA 19428-2959 236

Introduction

Recently, environmental awareness and concern over the rapid exhaustion of fossil fuels have led to an increased popularity of biofuels as an alternative fuel for avia- tion. The International Civil Aviation Organization (ICAO) set a goal that the global aviation industry approach “carbon neutrality” by 2020 and cut emissions in half by 2050 compared to 2005. To achieve that goal, countries around the world have done a lot of work to search for alternative fuels. Now, we have already reached a consen- sus that development of synthetic fuels, such as biofuels, is a practical way to reduce CO2 emissions [1].

ASTM International has already issue a standard (ASTM D7566 [2]) in 2009 to

prescribe the properties limitation and manufacturing of aviation turbine fuel that consists of conventional and synthetic blending components. In China, the Civil Aviation Administration of China (CAAC) has already approved Sinopec No. 1 bio- fuel formula and production and issued a Chinese Technical Standard Order (CTSO-2C701 [3]) to prescribe the synthetic hydrocarbon manufacturing in China. ASTM D7566 and CTSO-2C701 standards de?ned the maximum volume ratio of synthetic hydrocarbon in the blend fuel as both 50 %. However, the proposal of maximum “50 %” volume ratio of synthetic hydrocarbon allowed in the blend is based on current experience, because more than 50 % of synthetic hydrocarbon in the blend would lead to a lower aromatic content in the fuel, which may lead to fuel- tank leakage issues. Some reports revealed that fuel-tank leakage occurred frequently because of long-term use of the lower aromatic fuel in China.

Even though synthetic hydrocarbon can be produced from biomass and hydro- genated fats and oils by hydroprocessed esters and fatty acid (HEFAs) processes, the composition and properties of hydrocarbons are different from conventional hydro- carbons. This would in?uence the performance of aircraft fuel system materials, especially fuel-tank sealants [4].

In this research, the widely used fuel-tank polysul?de sealants PR-1422, class B-2, and PR-1440, class B-2, were selected as model sealants, and the impacts of the ratio of synthetic hydrocarbons in the biofuel blended with Chinese No. 3 jet fuel were systematically studied. The compatibilities of those two sealants with synthe- sized biofuels were thoroughly studied by comparing the tensile strength, elongation, and volume swell and hardness properties data. This research will be useful as a guide for biofuel application and promotion of the application of biofuels in China.

Experimental

SEALANT PREPARATION

Two different commonly used polysul?de fuel-tank sealants were selected in this research and provided by PPG Industries. These two sealants made from polysul?de are widely used in Boeing commercial aircraft. Detailed information about the seal- ants is shown in Table 1. The procedure to prepare the sealant is as follows: use weight-appropriate base and curing agents according to the ratios and instructions indicated in the product manual. Then thoroughly mix the entire contents on a smooth glass surface with a spatula while avoiding fast stirring to reduce the genera- tion of gas bubbles. The well-mixed blend was injected into a dedicated dispensing

TABLE 1

Properties of sealants.

Sealants Type Properties Specification

PR-1422, class B-2 Polysul?de, dichromate cured SAE-AMS-S-8802 type I

PR-1440, class B-2 Polysul?de, manganese cured SAE-AMS-S-8802 type II

gun, and the uncured sealant was obtained by injecting the mixture into the mold. The sealant was cured for 14 days at 25○C with 50 % relative humidity. When the ultimate cured hardness of the sealant was above 50 A, the sealant was regarded as quali?ed.

TEST FLUID PREPARATION

The fuel used in this experiment is shown in Table 2. The baseline test ?uid was jet reference fuel (JRF). The formulation of the JRF is shown in Table 3. JRF was pre- pared according to ASTM D4054 [5] and regarded as representative of or a surro- gate for typical kerosene-type fuels. Biofuel refers to pure synthetic hydrocarbon, is derived from waste cooking vegetable oils, and produced by hydroprocessed esters and fatty acids. Blend fuel refers to the blend of pure component with No.3 jet fuel; the blend ratio is 50/50.

THE COMPONENTS OF BIOFUEL

The biofuel’s feedstock was derived from waste cooking oil; the main component was vegetable oils gathered from Beijing restaurants. The production process was divided into four steps: ?rst, pretreat feedstock and purify, remove the heavy metal ion and phosphate; second, conduct hydrogenation treatment, remove oxygen and other impurities. The last two steps were the isomerization process and product sep- aration; and then synthetic hydrocarbon and biofuels were obtained. The total pro- duction process yields hydroprocessed esters and fatty acids (HEFAs) according to ASTM D7566. All of the properties meet the requirements of ASTM D7566. The test results are shown in Table 4.

SEALANT COMPATIBILITY TESTS

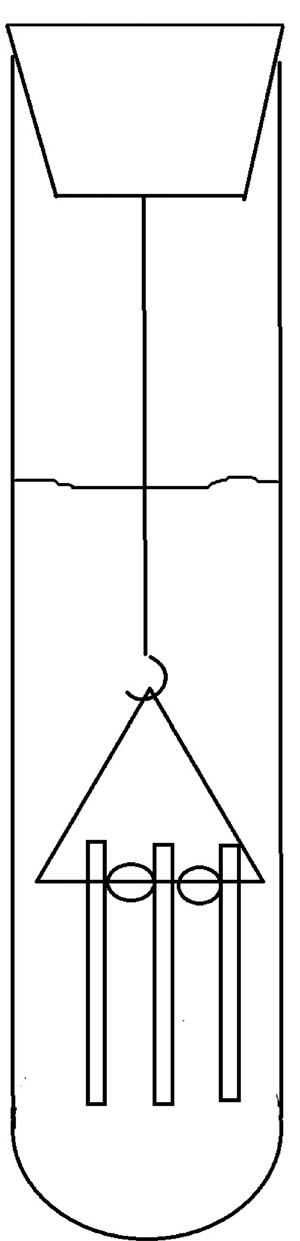

The experiments exactly followed ASTM D471 [13] test methods for the rubber property effect of liquids. During the experiment, the well-prepared specimens were soaped in the test ?uid at 93○C for 28 days, and the resulting deterioration was determined by measuring the changes in physical properties, such as changes in ten- sile strength, elongation at break, and hardness and volume change, before and after immersion in the test liquid. The test apparatus is shown in Fig. 1. The entire test

TABLE 2

List of fuels used in the experiments.

Test Fuel Type | Resources | Ratio, vol. % | Aromatics, vol. % |

Jet reference fuel (JRF) | Prepared according to ASTM D4054 | 100 % | 25 |

Biofuel | Derived from cooked oil | 100 % | 0 |

Blended fuel | Biofuel/No. 3 jet fuel | 50/50 | 8.4 |

TABLE 3 | |

The formulation of jet reference fuel. |

Type | Component | Volume % |

Paraf?ns | Exxsol D40 | 37.1 % |

| Exxsol D80 | 37.1 % |

Aromatics | Aromatic 100 | 7.5 % |

| Aromatic 150 | 15 % |

| Aromatic 200 | 2.5 % |

Sulfur | tert-Butyl disul?de | 0.73 % |

Mercaptan | Decanethiol | 0.01 % |

Fuel system icing inhibitor | DiEGME | 0.15 % |

Lubricity improver | According to the speci?cation | Proper amount |

Corrosion inhibitor | | |

apparatus was immersed in an oil bath to maintain the test temperature; glass beads were used in the liquid as a bumper and to separate the specimens and stopper on the top.

Tensile Strength and Elongation—

The test sealant plates were prepared using the dumbbell-shaped Die C according to ASTM D412 [14]. The tension speed was set as 500 6 50 mm/min. The maximum tensile strength and break elongation of the three specimens were calculated and the results averaged, before and after immersion in the 150 ml test liquid.

Hardness—

Hardness values before and after soaking in the test ?uids were determined using a Shaw A hardness tester.

Volume Swell Change—

Before the experiment, the sealant samples (size 25 mm × 50 mm × 2 mm rectangu- lar plates) were weighted in the air (M1) and in the distillated water (M2). Then the samples were completely soaped into tubes containing 100 ml test ?uid. Because of the test liquid volatilability, the test tube should be tightly ?tted with a stopper and a re?ux condenser. At the end of the experiment, the soaped sealants were thoroughly cleaned with acetone and weighted in air (M3) and in distillated water (M4). The volume change was calculated as follow:

TABLE 4

Test report of bio-SPK.

Property Method D7566 Requirement Biofuel Acidity, total mg KOH/g ASTM D3242 [6] Maximum 0.015 0.003

Existent gum, mg/100 mL ASTM D381 [7] Maximum 7 1.00

Density at 15.5○C, kg/m3 ASTM D4052 [8] 0.730 ~ 0.770 0.7669

Sulfur, mg/kg ASTM D5453 [9] Maximum 15 0.8

Flash point/ ○C ASTM D56 [10] Minimum 38 48

Water, mg/kg ASTM D6304 [11] Maximum 75 31

FAME, mg/kg IP 590 [12] Maximum 5 <4.5

FIG. 1

FIG. 1

Test apparatus.

TABLE 5

The swell ability data of two polysul?de sealants after 28 days soaked into the test fuel.

Material | Condition | D4054 Requirements | Test Results | Allowable Variation from JRF | Variation | Result Judgment |

PR-1422 B-2 | Unaged | — | — | — | — | — |

| JRF | 0 %–20 % | 6.4 % | — | — | Quali?ed |

| Biofuel | 0 %–20 % | —3.0 % | þ5 % | —9.4 % | Disquali?ed |

| Blended fuel | 0 %–20 % | —0.5 % | þ5 % | —7.5 % | Disquali?ed |

PR-1440 B-2 | Unaged | — | — | — | — | — |

| JRF | 0 %–20 % | 0.1 % | — | — | Quali?ed |

| Biofuel | 0 %–20 % | —6.7 % | þ5 % | —6.8 % | Disquali?ed |

| Blended fuel | 0 %–20 % | —5% | þ5 % | —5.1 % | Disquali?ed |

Table 5. The blended fuels were a biofuel blend with Chinese No. 3 jet fuel with a volume ratio of 50/50 [15].

When the JRF was used, the volume increase of PR-1422 B-2 was 6.4 vol. %. When the sealant was soaped in the pure biofuel component or blended fuel, ASTM D4054 required that the sealant volume change should range from 0 % to 20 vol. % and the allowable variation compared to JRF should be less than 5 vol. %. If the results fell out of this range, the fuel was disquali?ed. The experiments demonstrated that if sealants were soaped in the neat biofuel or biofuel blend with conventional No. 3 jet fuel, both PR-1422 B-2 and PR-1440 B-2 sealants shrunk. The volume shrinkage for PR-1422 B-2 and PR-1440 B-2 was 3.0 vol. % and 6.7 vol. %, and vari- ation from JRF was —9.4 vol. % and —7.5 vol. % [16–18].

The reason for the sealant shrinkage was low aromatics content in the test fuels. The aromatics content for neat biofuel component, blended fuel, and JRF was 0 %,

8.4 %, and 25 %, respectively. The ability of fuel-tank sealants to swell heavily depended on the aromatic content in the fuel. One explanation was that neat biofuel components consisted of n-paraf?n and iso-paraf?n, which are non-polar molecules. It was dif?cult to form hydrogen bonds between polysul?de molecules and alkane. However, the sealants’ ability to swell increased with increased aromatic content in the fuel as a result of the formation of hydrogen bonds and an increase in hydrogen donors.

Another explanation was that two polysul?de sealants had high density, high adhesive strength, and high fracture strength. They had regular structure and pos- sessed a high degree of cross linking after curing; thus, it was dif?cult to form hydro- gen bonds with aromatic components. This also reduced the ability of aromatic components to swell to its structure. Moreover, at high temperatures, the paraf?n in the ?uid could facilitate the extraction of tacki?ers, plasticizers, and other small mol- ecules in the rubbers, leading to an increased chance of volume shrinkage.

TABLE 6

The mechanical data of PR-1422 B-2 before and after immersing in different fuels.

Items | Condition | D4054 Requirements | Test Results | Allowable Variation from JRF | Variation | Result Judgment |

Tensile Strength (psi) | Unaged | >200 | 487 | — | — | Quali?ed |

| JRF | >200 | 344 | — | — | Quali?ed |

| Biofuel | >200 | 435 | Decrease 35 | þ91 | Quali?ed |

| Blended fuel | >200 | 413 | Decrease 35 | þ69 | Quali?ed |

Elongation | Unaged | >150 % | 497 % | — | — | Quali?ed |

| JRF | >150 % | 314 % | — | — | Quali?ed |

| Biofuel | >150 % | 251 % | Decrease 25 % | —63 % | Disquali?ed |

| Blended fuel | >150 % | 283 % | Decrease 25 % | —31 % | Disquali?ed |

Hardness | Unaged | >35 | 59 | — | — | Quali?ed |

| JRF | >35 | 51 | — | — | Quali?ed |

| Biofuel | >35 | 57 | 65 | þ6 | Disquali?ed |

| Blended fuel | >35 | 54 | 65 | þ3 | Quali?ed |

TABLE 7

The mechanical data of PR-1440 B-2 before and after immersing in different fuels.

—10 %

component content was higher than 50 vol. % (or speci?c value needed) in the test ?uid, it would lead to the shrinkage of the sealants and decrease the volume swell ability of sealants. The high volume of synthetic hydrocarbon in the blend would also cause the decrease in the mechanical properties of sealant deviation of elonga- tion, hardness, and tensile strength from the baseline.

The test results showed that the biofuel had poor compatibility with non- metallic material because of the low aromatic content. It easily causes the shrinkage of aircraft tank sealant. Even blended with the conventional jet fuel with volume ratios up to 50/50, the fuel also failed at the test of elongation and hardness. To pre- vent fuel leakage, great attention should be paid to the blend ratio of biofuels with conventional jet fuel. This would control the blend fuel at higher aromatics content levels to prevent aircraft fuel-tank leakage.

ACKNOWLEDGMENTS

The writers thank the Civil Aviation Administration of China for ?nancial support of this work.

References

- Haseeb, A., Masjuki, H., and Siang, C., “Compatibility of Elastomers in Palm Biodiesel,” Renew. Energ. J., Vol. 35, No. 10, 2010, pp. 2356–2361.

- ASTM D7566-14: Standard Speci?cation for Aviation Turbine Fuel Containing

Synthesized Hydrocarbons, ASTM International, West Conshohocken, PA, 2014, www.astm.org.

- CTSO-2C701, “Aviation Jet Fuel Containing Synthesized Hydrocarbons,” Chi- nese Technical Standard Order, CAAC, Beijing, 2013.

- Kai, C., Hua, L., and Zuxi, X., “The Impacts of Aromatic Contents in Aviation Jet Fuel on the Volume Swell of the Aircraft Fuel Tank Sealants,” SAE Int. J. Aerosp., Vol. 6, No. 1, 2013, pp. 350–354.

- ASTM D4054-14: Standard Practice for Quali?cation and Approval of New Aviation Turbine Fuels and Fuel Additives, ASTM International, West Consho- hocken, PA, 2014, www.astm.org.

- ASTM D3242-11: Test Method for Acidity in Aviation Turbine Fuel, ASTM International, West Conshohocken, PA, 2011, www.astm.org.

- ASTM D381-12: Standard Test Method for Gum Content in Fuels by Jet Evap- oration, ASTM International, West Conshohocken, PA, 2012, www.astm.org.

- ASTM D4052-11: Standard Test Method for Density, Relative Density, and API Gravity of Liquids by Digital Density Meter, ASTM International, West Conshohocken, PA, 2011, www.astm.org.

- ASTM D5453-12: Standard Test Method for Determination of Total Sulfur in Light Hydrocarbons, Spark Ignition Engine Fuel, Diesel Engine Fuel, and Engine Oil by Ultraviolet Fluorescence, ASTM International, West Consho- hocken, PA, 2012, www.astm.org.

- ASTM D56-10: Standard Test Method for Flash Point by Tag Closed Cup Tes- ter, ASTM International, West Conshohocken, PA, 2010, www.astm.org.

- ASTM D6304-07: Standard Test Method for Determination of Water in Petro- leum Products, Lubricating Oils, and Additives by Coulometric Karl Fischer Titration, ASTM International, West Conshohocken, PA, 2007, www.astm.org.

- IP 590-10, “Determination of Fatty Acid Methyl Esters (FAME) in Aviation Turbine Fuel—HPLC Evaporative Light Scattering Detector Method,” Energy Institute, London, 2010.

- ASTM D471-12: Standard Test Method for Rubber Property—Effect of Liquid, ASTM International, West Conshohocken, PA, 2012, www.astm.org.

- ASTM D412-13: Standard Test Methods for Vulcanized Rubber and Thermo- plastic Elastomers—Tension, ASTM International, West Conshohocken, PA, 2013, www.astm.org.

- Thomas, E., “Fluoroelastomer Compatibility With Bioalcohol Fuels,” SAE Int. J. Fuels Lubr., Vol. 2, No. 1, 2009, pp. 462–473.

- Forest, C. and Muzzell, P., “Fischer-Tropsch Fuels: Why Are They of Interest to the United States Military?” Technical Paper 2005-01-1807, SAE Interna- tional, Warrendale, PA, 2005.

- DeWitt, M. J., Corporan, E., Graham, J., and Minus, D., “Effects of Aromatic Type and Concentration in Fischer-Tropsch Fuel on Emissions Production and Material Compatibility,” Energ. Fuel., Vol. 22, No. 4, 2008, pp. 2411–2418.

- Lamprecht, D., “Elastomer Compatibility of Blends of Biodiesel and Fischer-

Tropsch Diesel,” Technical Paper 2007-01-0029, SAE International, Warren- dale, PA, 2007.