2013-01-9001

Published 09/15/2013 Copyright © 2013 SAE International doi:10.4271/2013-01-9001

Published 09/15/2013 Copyright © 2013 SAE International doi:10.4271/2013-01-9001

saeaero.saejournals.org

The Impacts of Aromatic Contents in Aviation Jet Fuel on the Volume Swell of the Aircraft Fuel Tank Sealants

Kai Chen, Hua Liu and Zuxi xia

Civil Aviation Administration of China

ABSTRACT

The impacts of aromatic contents in the aviation jet fuel on the volume swell of fuel tank polythioether and polysulfide sealants were systematically studied in this research. The experimental results revealed the sealant volume swell was dramatically increased as the aromatic content in the fuel was increased. The volume of the PR 1440 polysulfide manganese cured sealant was shrunk when the sealant was soaped in the aviation fuel with aromatic volume content less than 8 vol. % for 28 days at 93°C. The volume of the tested polythioether sealants was never shrunk at the same operating conditions. The experimental results also demonstrated the addition of various additives into the aviation fuel could effectively increase the volume swell of the sealant, increasing the sealant sealing properties. The shrinkage of the PR1440 polysulfide sealant soaped in the low aromatic content fuel at high temperature may be attributed to the material high density, the well-arrangement of the material structure and the high cross linking degree of polymer. This may also explain the fuel leakage phenomena in some aircrafts injected with low aromatic contents fuel in China.

CITATION: Chen, K., Liu, H. and xia, Z., "The Impacts of Aromatic Contents in Aviation Jet Fuel on the Volume Swell of the Aircraft Fuel Tank Sealants," SAE Int. J. Aerosp. 6(1):2013, doi:10.4271/2013-01-9001.

INTRODUCTION

The high aromatic contents in the jet fuel, especially the naphthalene-based hydrocarbon, could not only lower the fuel combustion performance but also lead to generate more particulate matter (PM) during engine operation. The PM would easily deposit inside the combustion chamber or on the engine blades, causing reduced air flow in the channel and shortage of engine lifetime. More importantly, the PM had been linked to a range of serious respiratory and cardiovascular health problems and long term exposures to PM might result in tens of thousands of excess deaths per year. Thus, there were strict specification limit requirements for aromatic contents in the jet fuel in national standards all over the world. In China the standard for civil aviation jet fuel (GB 6537) required the maximum aromatic contents in the fuel should be no more than 25 vol.%, which was in accordance with American standard ASTM D 1655 and England standard DEF STAN 91-91. Even though there was no minimum limit for aromatic content in the fuel, due to the usage of polysulfide and polythioether as aircraft fuel tank sealants, the aromatic contents in the fuel should not be too low since the fuel must include swellability to ensure the tightness of the aircraft fuel tank. The paraffin in the aviation fuel had low ability to the seal swell and under the environment of high temperature the polysulfide even shrunk.

The responsibility of fuel and chemical airworthiness certification center of civil aviation of administration of China (CAAC) was to continuously monitor the aviation fuel quality to ensure the jet fuel quality and safety. From our long term monitor we found out the aromatic contents in the imported Jet A-1 were typically 10 to 25 vol.% while the aromatic contents in some domestic manufactured No.3 jet fuels were less than 8 vol.%. In some extremely case the aromatic content in the fuel was 1.4 vol. % much lower than the average aromatic contents in the imported jet fuel. However, the newest standard specification for aviation turbine fuel containing synthesized hydrocarbons (ASTM D 7566-2011a) provided both minimum and maximum aromatic contents limit requirements. The standards required the aromatic contents in the fuel should be no less than 8 vol. %. There were occasional aircraft fuel tank leakage reports from aircrew and airline department of aircraft maintenance. We suspected the fuel tank leakage may be associated with the seal shrinkage due to the poor swelling characteristics of the added fuel.

In this research the widely used fuel tank polysulfide sealants PR-1440, PR-1776 and polythioether sealants PR-1826, PR-1828 were selected as model sealants and the impacts of aromatic contents in the aviation jet fuel on the volume swell were systematically studied. The study also

350

Chen et al / SAE Int. J. Aerosp. / Volume 6, Issue 1(September 2013) 351

compared the influence of fuel additives on the seal swell ability. The compatibilities of those four sealants with synthesized biofuel were thoroughly studied and recommendation of biofuel application in the civil aviation was also provided in this paper. The experimental results would provide better guidance on aviation fuel qualify control and give supportive information to the department of civil aviation administration on publishing aviation circulars.

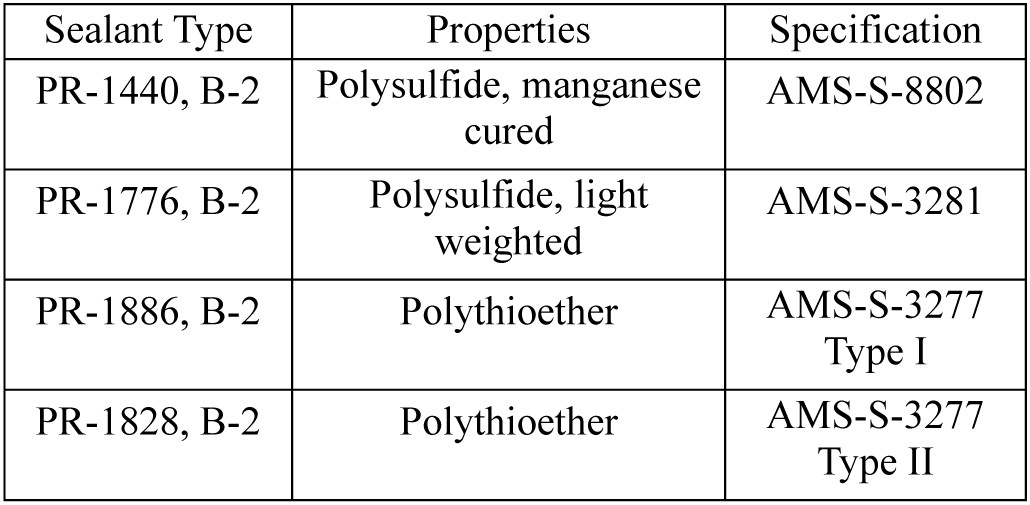

EXPERIMENTAL

Sealant Preparation: Four different common used polysulfide and polythioether sealants were selected in this research and provided by PPG Industries. The detailed information about the sealants was illustrated in table 1. The procedure to prepare the sealant was as follows: weight appropriate base and curing agent according to the ratios and instructions indicated in the product manual. Then thoroughly mix entire contents on a smooth glass surface with spatula while avoid fast stir to reduce the generation of gas bubble. The well mixed mixture was injected into a dedicated dispensing gun and the uncured sealant was obtained by injection of mixture into the mold. The sealant was cured for 14 days under 25°C with 50% relative humidity. When the ultimate cured hardness of the sealant was above 50 A the sealant was regarded as qualified.

Table 1. Properties of Sealants

Test Fluid Preparation: The baseline test fluids were prepared according to ASTM D 4054. The formulation of the Jet Reference Fuel (JRF) was as follows: Exxsol D40 37.1 vol. %, Exxsol D80 37.1 vol. %, Aromatic 100 7.5vol. %, Aromatic 150 15vol. %, Aromatic 200 2.5 vol. %, tert-Butyl Disulfide 0.73 vol. %, Decanethiol 0.01 vol. %, DiEGME

0.15 vol. %. The test fluids containing different volume percentage aromatic contents were prepared as follows: Based on the formulation of JRF prepare paraffin solution (D40:D80 = 1:1) and aromatic solution (A100:A150:A200 = 3:6:1). Then use the pre-prepared paraffin and aromatic solution to make blend containing 0 vol. %, 4 vol. %, 8 vol.

% and 12 vol. % aromatic solution. After that add proper amount of sulfur, mercaptan, fuel system icing inhibitor and lubricity improver into the blend, which was regarded as to be representative of, or a surrogate for, kerosene-type fuels. Besides the test fluids above another three kinds of jet fuels were provided in this research. No.3 Jet Fuel-1 was provided

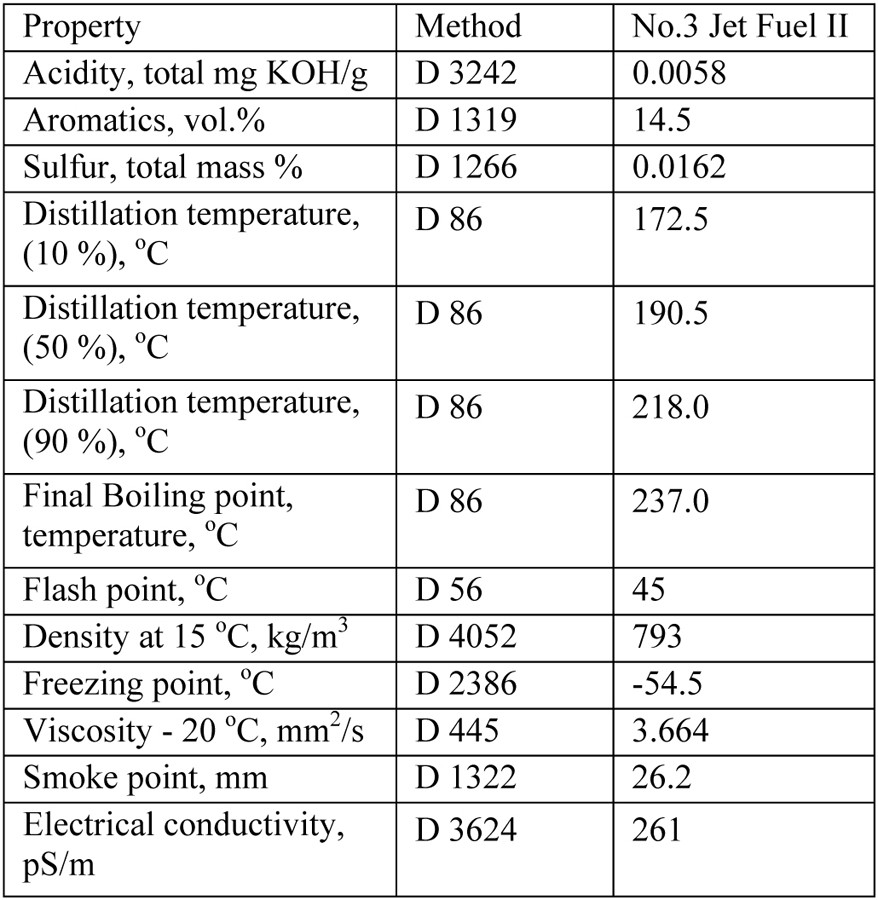

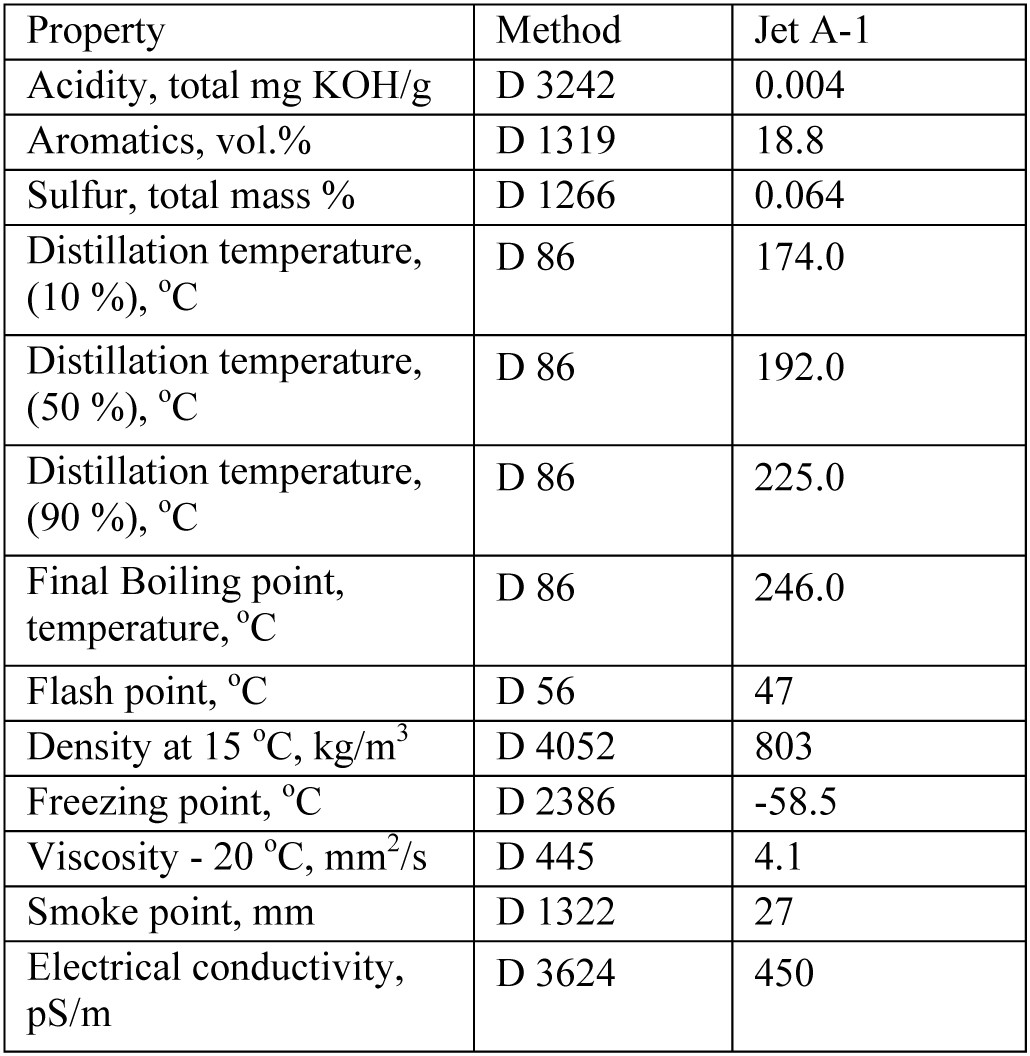

by Nanning refinery of PetroChina and No-3 Jet Fuel-2 was provided by Luoyang refinery of China Sinopec. Jet A-1 was imported from Korean arrival from port Shanghai. The physical and chemical properties of those three fuels were listed in table 2, 3, 4. We also tested the effects of aromatic content in aviation biofuel on seal swell ability. Both biofuel components tested here were produced from Jatropha curcas, one by PetroChina (Biofuel-1) and one by Sinopec (Biofuel-2). The pure biofuel components were then mixed with No.3 Jet fuel in the volume ratio of 50:50. Analysis indicated the aromatic content in the mixture was equal or higher than 8 vol. %.

Table2. Physical and Chemical Properties of No.3 Jet Fuel-1

Table3. Physical and Chemical Properties of No.3 Jet Fuel-2

Table3. Physical and Chemical Properties of No.3 Jet Fuel-2

352 Chen et al / SAE Int. J. Aerosp. / Volume 6, Issue 1(September 2013)

Table 4. Physical and Chemical Properties of Jet A-1

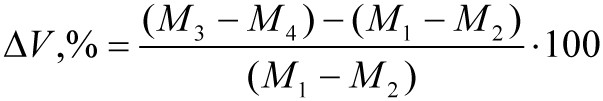

Sealant Volume Swell Ability Test: The experiments exactly followed the ASTM D 471 standard test method for rubber property-effect of liquids. During the experiment the well prepared specimens were soaped in the test fluid under definite conditions of temperature and time, the resulting deterioration was determined by measuring the changes in physical properties, such as changes in mass, volume, and dimension, before and after immersion in the test liquid. Before the experiment the sealant samples were weighted in the air (M1) and in the distillated water (M2). Then the samples were completely soaped into tubes containing 100 ml test fluid. Due to the test liquid volatile ability the test tube should be tightly fitted with a stopper and a reflux condenser. During the test the fluid sample should be maintained at 93

°C for 28 days with fluid sample replace at the 14th day. At the end of the experiment the soaped sealants were thoroughly cleaned with acetone and weighted in air (M3) and in distillated water (M4).The volume change was calculated as follows:

RESULTS AND DISCUSSION

The Relationship between Aromatic Content and Volume Swell Change of Aircraft Sealant

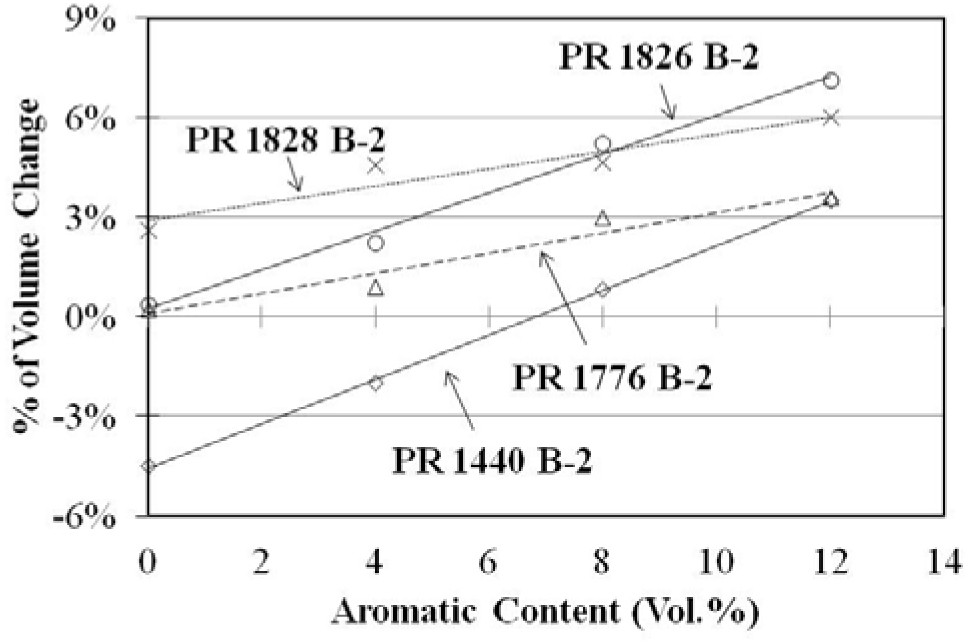

The experiments were conducted to investigate the influence of the standard jet fuel with aromatic content ranging from 0 vol. % to 12 vol. % on the seal swell ability and the results were illustrated in Figure 1. When the RJF

was used, whose aromatic content was 25 vol. %, the volume increase for PR 1440, PR 1776, PR 1826 and PR 1828 was

5.21 vol. %, 6.04 vol. %, 8.08 vol. % and 12.02 vol. % respectively. When the sealant was soaped in the test fuel ASTM D 4054 required the sealant volume change should be ranging from 0 % to 20 % and the allowable variation from RJF should be less than 5 vol. %. If the test results failed out of this range the fuel was regarded as disqualified. The experiments demonstrated as the aromatic content increased different sealants displayed different degree of volume swell increase and the volume increase was all within 5 % of its increase in RJF. However, the volume of sealant PR 1440 B-2 shrunk after 28 days exposure to the test fuel with aromatic content less than 8 vol. %. For instance, when there was no aromatic component in the fuel the volume of the PR 1440 B-2 decreased 4.71 vol. %. One explanation was that PR 1440 was the kind of sealant with high density, high adhesive strength and high fracture strength. It had regular structure and possessed high degree of cross linking after curing, thus difficult to form hydrogen bond with aromatic components. This also reduced the swellability of aromatic components to its structure. Moreover, at high temperature the paraffin in the fluid could facilitate the extraction of tackifiers, plasticizers and other small molecules in the rubbers, leading to the increase chance of volume shrinkage.

Figure 1. Impacts of aromatic contents in aviation fuel on the volume swell of aircraft fuel tank sealants

Even though the aromatic content could significantly influence the sealant volume swell ability the volume of PR 1776 B-2, PR 1826 B-2 and PR 1882 B-2 soaped in the low aromatic content fuel did not contract. This indicated the volume swellability was not only related to the aromatic content in the fuel but also connected with sealant itself properties and compositions. Due to the weak polarity of thioether bond, polythioether such as PR 1826 and PR 1828 was easy to form hydrogen bond with aromatic component and small amount of aromatics in fuel could lead to well swell of the volume.

Chen et al / SAE Int. J. Aerosp. / Volume 6, Issue 1(September 2013) 353

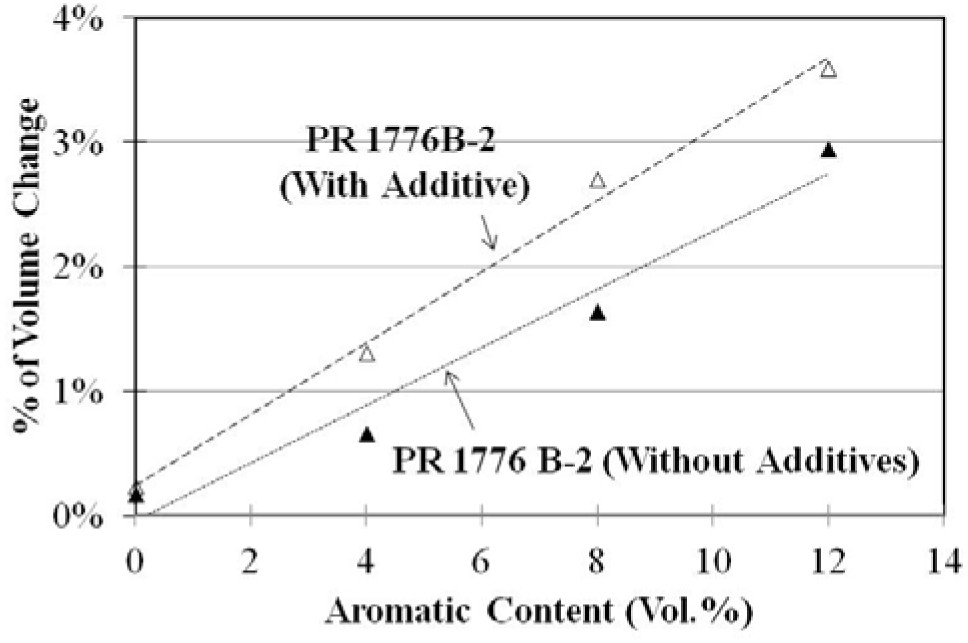

Effects of Fuel Additive on Volume Swell Change of Aircraft Sealant

We also investigated the impacts of fuel additives on volume swell of aircraft sealant. Figure 2 illustrated the effects of fuel additives on the volume swell of polysulfide lightweight sealants PR 1776 B-2. The hollow triangles in the figure represented the sealant volume change in the fuel with additives while the solid triangle delegated the sealant volume change in the fuel without additives. The fuel without additives consisted of only Paraffins Exxsol D40 and D80 and Aromatics Aromatic 100, 150 and 200. The fuel with additives also contained sulfur tert-butyl disulfide, mercaptan Decanethiol, fuel system icing inhibitor DiEGME and lubricity improver QPL-25017. The results well demonstrated the volume swell rate monotonously increased as the aromatic content increased in the fuel with or without additive. When the additives were added into the fuel the sealant volume swell rate was much higher than that without additives. This was partially because the mercaptan Decanethiol in the fuel could easily destroy the elastomers chain leading to the loose of the acting force within bonds and causing the swell of sealant volume.

Figure 2. Effects of fuel additives on the volume swell of polysulfide lightweight sealants

Comparison of Fuel Manufactured by Different Refineries on the Sealant Volume Swell

The theoretical study demonstrated the sealant volume swell was not only related to the aromatic content and the additive added in the fuel but also related to material itself properties. In industry due to the different catalysts and technologies applied in the manufacture different refineries would manufacture fuel with different properties with aromatic content ranging from 2 vol. % to 20 vol. % meanwhile other factors may also impact the elastomers volume change. We compared the influences of fuel manufactured by different refineries on the sealant volume swell.

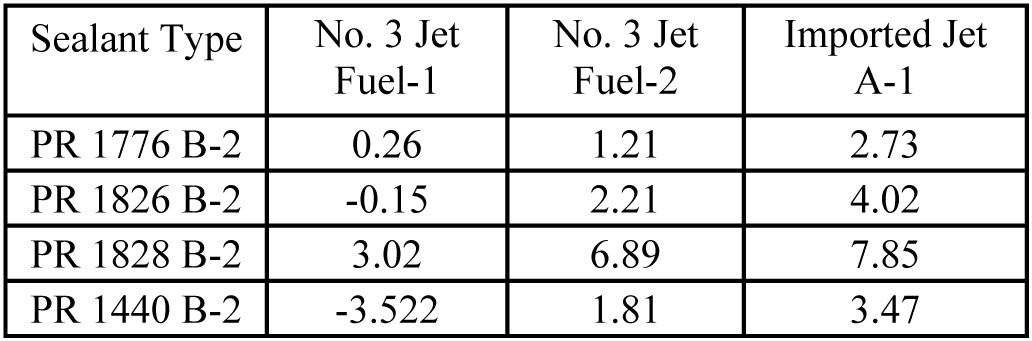

Table 5. Impact of manufacture technology on the volume swell of different sealants

Currently in China the techniques adopted for Jet fuel manufacture all included depth hydrorefining, which led to the low aromatic content in the final product. Even though the depth hydrorefining could remove naphthenic acid and mercaptan, improving the fuel combustion ability, thermal stability and cleanliness, it also caused the removal of aromatic compounds and natural antioxidant in the fuel, making the fuel easy to be oxidized. At high temperature the hyperoxide in the fuel would grow fast and those hyperoxide had strong erosion effect on the elastomers chain, making rubber losing its elasticity and aging in a short time. Even if the refinery in the developed countries also used hydrorefining technique due to the different source of the crude oil the aromatic content in the final product was always maintained above 15 vol. %. The investigation of aircraft fuel tank leakage showed that at fuel system working temperature use of hydrorefining jet fuel may easily cause the rubber sealant to lose its original physical properties. The experiments compared compatibility of four different sealants with three different jet fuels as shown in table 5. No.3 Jet Fuel-1 was provided by Nanning refinery of PetroChina and No-3 Jet Fuel-2 was provided by Luoyang refinery of China Sinopec. Jet A-1 was imported from Korean arrival from port Shanghai. The analysis of hydrocarbon types in liquid petroleum products by fluorescent indicator adsorption indicated the aromatic content in each fuel was 2.1 vol. %,

14.5 vol. %, and 18.8 vol. % respectively. As expected the polythioether soaped in the low aromatic content fuel showed volume shrinkage after 28 days test. The manganese cure polysulfide elastomers also demonstrated volume contraction. The sealant swell ability always satisfied the principle of similar compatibility, which meant the polar material was much easier to dissolve in the polar solvent and nonpolar material was easier to dissolve in nonpolar solvent. The aviation fuel was mainly consisted of normal alkane and branched paraffin, which itself could not be used as a hydrogen donor. However, the alkylbenzene in the fuel was polar molecular and can be used as week hydrogen donor. The elastomers volume swell ability was a function of fuel composition and hydrogen supply ability. Thus, as the aromatic content increased in the fuel the sealant volume swell ability was enhanced.

354 Chen et al / SAE Int. J. Aerosp. / Volume 6, Issue 1(September 2013)

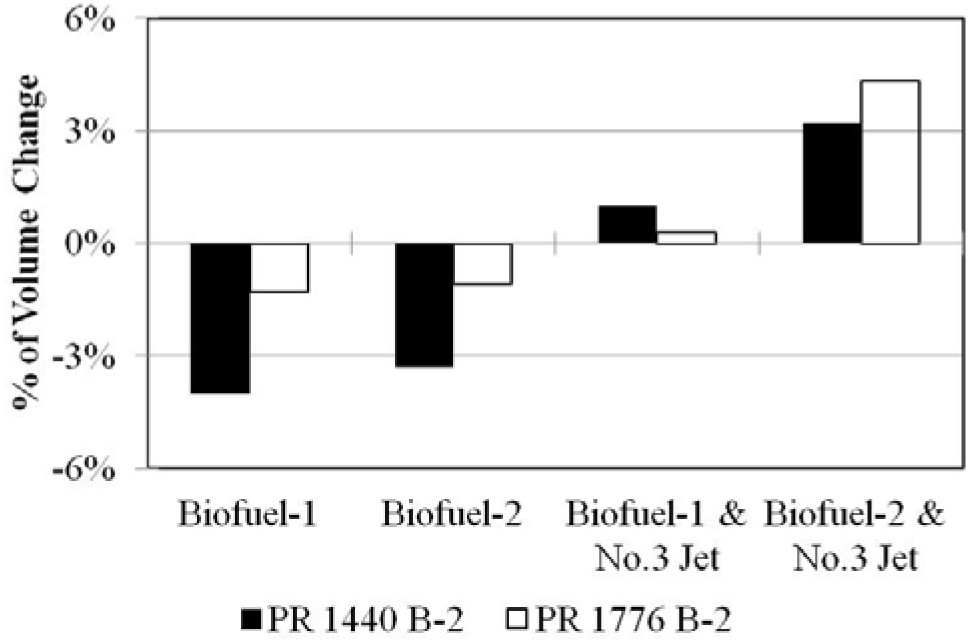

Figure 3. Seal swell properties with Biofuel

The Compatibility of Elastomers with Biofuel

The application of biofuel in the aviation industry was believed to reduce the green gas emission and particulate matters. The pure aviation biofuel prepared by Fischer- Tropsch or HEFA process had been shown to exhibit excellent thermal-oxidative stability characteristics with significantly lower particulate matter (PM) combustion emissions compared to conventional petroleum-derived fuels. However, the biofuels were typically comprised solely of iso- and n-alkanes and did not contain heteroatoms, cyclic compounds, or aromatics. With respect to volume swell, there were also potential concerns that transition of operation from petroleum-derived fuels (typically 10-25% aromatic content) would result in seal shrinkage and leaks due to the poor swelling characteristics of the biofuel. We studied the compatibility of elastomers with two biofuels compounds and biofuel blends of 50:50 volume ratios with traditional.jet fuel. Those two biofuel and their blends were provided by PetroChina and Sinopec respectively. The analysis of both biofuel components indicated trace amount of aromatic content, less than 1 vol. %. The experimental results conformed to our expectation as both PR 1440 and PR 1776 showed certain degree of contraction as shown in Figure 3. When the biofuel was blended with No.3 jet fuel both elastomers illustrated some expansion since the aromatic content in the fuel was sufficient to lead to formation of hydrogen bond between aromatic compound and sealant.

SUMMARY/CONCLUSIONS

The aromatic content in the jet fuel would significantly influence the jet fuel quality. The extreme low aromatic content in the jet fuel would cause poor swell ability of the sealant and influence the its sealing effect in the fuel system. The experiments conducted in this research well demonstrated as the aromatic content increased in the fuel the sealant volume swell rate would increase dramatically. The sealant volume swell ability was not only related to the fuel

aromatic content but also related to the rubber material properties, such as its composition, processing techniques and the cross linking degree after sulfating. In order to make the sealant possess proper swell ability it is better to include some straight-run distillation into the depth refining product and effectively control the aromatic content in the fuel ranging between 10 vol. % to 20 vol. %/

REFERENCES

- Silverman, B., “Effects of High Aromatic Aviation Fuel on Sealant Systems,” SAE Technical Paper 800881, 1980, doi:10.4271/800881.

- Thomas, E., “Fluoroelastomer Compatibility with Bioalcohol Fuels,”

SAE Int. J. Fuels Lubr. 2(1):462-473, 2009, doi:10.4271/2009-01-0994.

- Forest, C. and Muzzell, P., “Fischer-Tropsch Fuels: Why Are They of Interest to the United States Military?,” SAE Technical Paper 2005-01-1807, 2005, doi:10.4271/2005-01-1807.

- Haseeb, A., Masjuki, H.H., Siang, C.T. and Fazal, M.A. “Compatibility of Elastomers in Palm Biodiesel” Renewable Energy 35(10):2356-2361, 2010, doi:10.1016/j.renene.2010.03.011

- DeWitt, M.J., Corporan, E., Graham, J., and Minus, D. “Effects of Aromatic Type and Concentration in Fischer-Tropsch Fuel on Emissions Production and Material Compatibility” Energy & Fuels 22(4): 2411-2418, 2008, doi:10.1021/ef8001179

- Lamprecht, D., “Elastomer Compatibility of Blends of Biodiesel and Fischer-Tropsch Diesel,” SAE Technical Paper 2007-01-0029, 2007, doi:10.4271/2007-01-0029.

CONTACT INFORMATION

Contact Information: Dr Kai Chen chenkai@fccc.org.cn

The Fuel & Chemical Airworthiness Center of Civil Aviation Administration of China

ACKNOWLEDGMENTS

We would like to thank Civil Aviation Administration of China for financial support for this work.